Monday, July 7 | 2:00pm – 5:00pm

Organized by Computational Heat Transfer (K20) Technical Committee

Modeling and Simulation of Heat Transfer and Thermofluidic Systems with Simscape Fluids

Presenters:

- Andrew Greff (Senior Application Engineer, MathWorks)

- Mehdi Vahab (Manager for Mechanical and Aerospace Engineering, MathWorks)

Join us for a hands-on session for computational modeling and simulation of heat transfer and thermofluidic systems. By the end of this workshop, you will have the working experience of creating such systems in Simscape Fluids and using them for engineering design and implementation. Attendees are encouraged to bring their laptops to the session. A workshop license for MathWorks products will be shared with attendees before the conference.

Session 1 (1.5 hours): Fundamentals & Basic Simulations

- Introduction to Simulink and Simscape Fluids

- Example I: Modeling heat transfer through solid geometries

- Example II: Thermal exchange in piping systems

Session 2 (1.5 hours): Applied Systems & Advanced Features

- Example III: Heat exchanger modeling

- Parametrizing a simple heat exchanger based on fluid properties and geometry

- Understanding initial conditions

- Example IV: EV battery cooling system design

- Challenges in thermal management for electric vehicles

- Simulation of cooling strategies to maintain optimal battery temperature

- Walkthrough EV Battery Cooling System Design demo

- Advanced Simscape Fluids features

- Matching heat exchangers with performance data

- Simulating complex geometries and varying operating conditions

- Importing REFPROP fluids

- Real-world applications and Q&A session

Presenter Biographies

Andrew Greff is a senior application engineer at MathWorks. He specializes in physical modeling using Simscape and focuses on thermal, fluid, and multibody systems. Before joining MathWorks, Andrew worked for GM and Stellantis developing advanced hardware and controls for engines. He obtained his PhD in mechanical engineering from the University of Alabama.

Mehdi Vahab is the Academic Manager for Mechanical and Aerospace Engineering at MathWorks. He specializes in physical and computational modeling for fluid and thermal systems. Before MathWorks, he developed numerical methods for multiphase systems and phase-change dynamics, applied to problems like heat transfer in pool boiling, hypersonic vehicle thermal management, and snow melting in open waters. At MathWorks, he assists researchers, faculty, and students by finding better solutions for their research and teaching challenges.

Monday, July 7, 3:00pm – 5:00pm

Fee $35

Modeling Methods for High-Temperature Particle Flows in Energy Storage, Chemical Reactors, and Additive Manufacturing

Workshop Description: This workshop will focus on a series of short tutorials/presentations that discuss modeling flow physics and heat transfer (conduction, convection, radiation) in particle flow systems.

Workshop Agenda*:

Description:This session introduces and compares three foundational particle modeling approaches used to simulate particulate systems in engineering and scientific applications: Discrete Element Methods (DEM), Eulerian–Lagrangian models, and Eulerian–Eulerian multiphase models incorporating μ(I) rheology. The session is designed to equip future researchers with a broad understanding of each method's governing assumptions, computational requirements, and practical use cases. Emphasis will be placed on selecting the appropriate modeling approach based on the physical behavior of interest, available computational resources, and desired level of resolution. Participants will be provided with curated resources, example codes, and pathways to begin implementing each method in their own research.

Dr. Andrew J. Schrader (Presenter) Dr. Andrew J. Schrader is an Assistant Professor of Mechanical and Aerospace Engineering at the University of Dayton, where he leads the Dayton Thermal Applications (DaTA) Laboratory. He earned his B.S. in Mechanical Engineering from Valparaiso University (2014), and M.S. (2017) and Ph.D. (2019) degrees from the Georgia Institute of Technology, where he studied high-temperature granular flows and solar thermochemical systems under Dr. Peter Loutzenhiser. Following his doctoral work, he served as a postdoctoral fellow at Georgia Tech, advancing modeling tools for granular media. At the University o Dayton, Dr. Schrader's research focuses on particle-based thermal energy storage and its integration with supercritical CO₂ power cycles. He also founded the University of Dayton Supercritical CO₂ Interdisciplinary Research Center, fostering collaboration among academia, government, and industry to advance next-generation energy technologies in Southwest Ohio.

Description: With the ongoing interest in particles for energy storage and concentrating solar power technologies, Sandia has been continuing to develop computational capabilities for discrete particle modeling by leveraging many existing projects and hardware. Recently, researchers at Sandia National Laboratories have coupled its in-house computational code suite, Sierra, with the open-source molecular dynamics code called the Large-scale Atomic/Molecular Massively Parallel Simulator (LAMMPS) to create a CFD-DEM capability that is able to utilize Sandia’s high-performance computing (HPC) resources. While the immense computational resources provided by HPCs extends the scale of particle problems that can be analyzed, challenges remain to increase the computational domain beyond submodels of specific particle-based applications. This talk will showcase the current CFD-DEM computational capability at SNL through exemplars while discussing many of the ongoing efforts to improve the coupling and computational efficiency for this application space.

Dr. Brantley Mills (Presenter) is a principal member of the technical staff at Sandia National Laboratories specializing in the computational thermal/fluid sciences. Dr. Mills has worked in a broad range of heat transfer and renewable energy topics including: concentrating solar power, thermal systems analysis, thermal-fluid cryogenics, reduced-order modeling, and nuclear energy. While also having an experimental background, some of Dr. Mills’ recent work has focused on the computational sciences with high-performance computing and the development of coupled, multi-physics models for particle-based concentrating solar power. Brantley Mills received his Ph.D. in nuclear engineering from the Georgia Institute of Technology in 2014 and his B.S. in mechanical engineering from Clemson University in 2009.

Dr. Christoph Goniva (Presenter) received his Ph.D. in Computational Fluid Dynamics in 2011, at the Johannes Kepler University (JKU) in Linz, Austria. From 2011 to 2014, he has been Senior Research Associate at the Department of Particulate Flow Modelling at JKU, where he headed a DEM and CFD-DEM modelling team together with Dr. Christoph Kloss. Dr. Christoph Goniva is co-founder and director of DCS Computing, the producer of the DEM software Aspherix® and the CFD-DEM software CFDEM®coupling.

Description: The Discrete Element Method (DEM) enables high-fidelity modeling of particle systems by resolving translational/rotational motion and contact forces between individual particles. However, scaling DEM to industrial applications—particularly when coupled with Computational Fluid Dynamics (CFD)—demands significant computational resources. This workshop presents a GPU-accelerated DEM solver designed to overcome these challenges through cost-effective parallelism and seamless integration with ANSYS Fluent. GPUs are uniquely suited for DEM due to their ability to execute thousands of simple, repetitive particle-force calculations in parallel. Unlike CPU clusters, which incur high costs for underutilized core capabilities, low-cost GPUs deliver superior performance for DEM’s arithmetic-heavy workload. The solver leverages this architecture to simulate millions of particles efficiently, avoiding the financial overhead of CPU-based systems. The solver imports ANSYS Fluent’s CFD mesh directly via Dynamic-Linked Libraries (DLLs), eliminating cross-platform communication delays. Fluent’s cell geometry—including tetrahedral, hexahedral, and polyhedral meshes—is used for particle-fluid/wall interactions, ensuring compatibility with complex industrial geometries. A streamlined particle-cell search algorithm removes the need for auxiliary grids, reducing memory usage while maintaining accuracy. A novel void fraction method further enhances robustness across unstructured or irregular meshes, critical for realistic fluid-particle systems. To maximize computational resources, the CFD (Fluent) and DEM solvers run concurrently: Fluent operates on the CPU for fluid dynamics, while the GPU handles all particle calculations. This concurrent execution avoids hardware idle time, enabling full utilization of available processing power. Performance benchmarks demonstrate significant speed improvements over both CPU-based and existing GPU-coupled DEM approaches, particularly for large-scale systems. By combining GPU parallelism, direct ANSYS Fluent integration, and optimized mesh handling, this solver provides a scalable, cost-effective solution for multiphase simulations—enabling high-resolution modeling of particle-laden flows without reliance on expensive infrastructure.

Dr. Alireza Kianimoqadam (Presenter) is a Postdoctoral Research Fellow at the University of Dayton working on particulate solar thermal energy systems. With a PhD in Mechanical Engineering from the University of Maine and a foundational background from Isfahan University of Technology, he architects advanced simulation frameworks that bridge high-performance computing, machine learning, and multiphysics modeling.

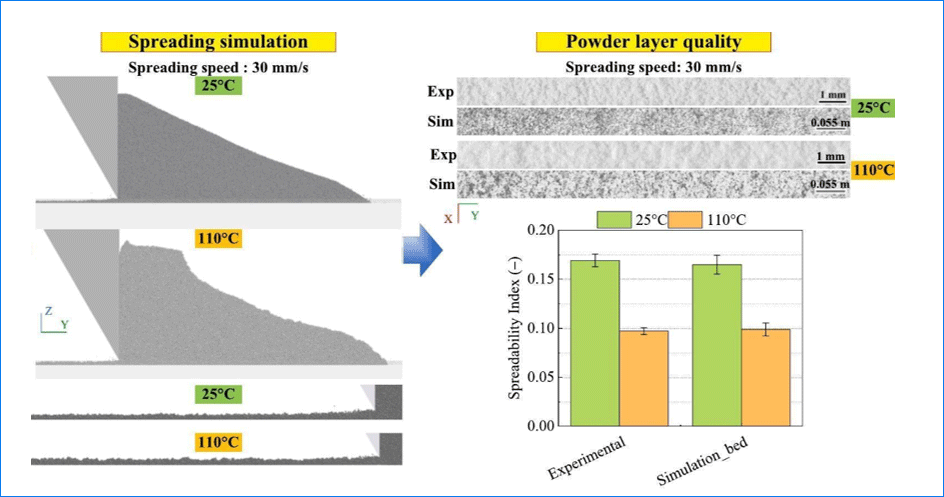

Description: In Powder Bed Fusion (PBF) additive manufacturing, the quality of the powder layer is vital for achieving high-density, defect-free parts. A smooth and uniformly packed layer ensures consistent energy absorption and proper layer bonding during the fusion process. Powder spreading is a key step that influences the homogeneity and stability of the deposited layer. Spreading speed significantly affects particle dynamics—higher speeds can increase particle inertia and reduce the time for rearrangement, resulting in unfilled regions and irregular surfaces. Temperature also plays an important role: at room temperature, lower interparticle cohesion promotes better flow and uniform deposition, whereas elevated temperatures enhance cohesion, leading to particle aggregation and reduced spreadability. These changes impact surface roughness and packing fraction, ultimately affecting the quality of the manufactured component. Numerical methods such as the Discrete Element Method (DEM) offer valuable insight by capturing particle-scale interactions and predicting powder behavior under various process conditions. By understanding the effects of spreading speed and temperature, more stable and optimized powder layering can be achieved, improving the overall efficiency and reliability of the PBF process.

Dr. Sina Zinatlou Ajabshir (Presenter) is currently a Postdoctoral Fellow in the Department of Industrial Engineering at the University of Salerno (UNISA), Italy. His research focuses on the properties of powders used in powder-based 3D printing methods. He holds a BSc and MSc in Materials Science and Engineering from the University of Tabriz and Sharif University of Technology (SUT), respectively. He earned his Ph.D. in Industrial Engineering with a specialization in Chemical Engineering from UNISA, with a dissertation centered on powder flowability and spreadability in powder bed fusion processes. Before joining the Powder Technology Group at UNISA, he served as a Research Assistant at SUT, where he worked on additive manufacturing and welding. His research interests include particle characterization, powder flow behavior, physical metallurgy, microstructure evolution, and the development of computational models using Discrete/Finite Element Methods.

Description: Gas turbine engines can be subject to damage from ingesting dust, ash, and debris. This can result in increased maintenance costs, downtime, and even engine failure. An inertial particle separator (IPS) is an inlet-mounted device that can remove sand, dust, and other harmful material from the engine flowpath. This system can minimize particulate ingestion during helicopter landings in austere brown-out conditions, increasing engine life and aircraft survivability. Typically, IPS systems have lower engine power losses than alternative engine inlet filtration technologies. Due to the competing demands of high particle separation and low total pressure costs, IPS designs must make a number of tradeoffs that affect both particle trajectories and flow path characteristics. Operational IPS designs may experience unsteady separated flows that lead to particles being ingested into the engine core flow. These unsteady flows are challenging to characterize even with a combination of modelling and testing. This presentation will review the relevant fluid and particle physics, testing and modelling approaches, and the current state of the art of IPS designs.

Dr. Brian Connolly (Presenter) is a Senior Research Engineer at Southwest Research Institute. His work focuses on computational modelling of multiphase, combustion, and hypersonic fluid flows.

Dr. Federico Munnichi (Presenter) is a Researcher in Computational Science at the National Renewable Energy Laboratory (NREL) developing numerical methods for multiphase flows applied to energy-related processes. His research is centered around flows with gas, liquid, and solid components in extreme conditions such as high-speed separation systems, low gravity bioreactors, plastic pyrolysis, and fibrilization of sheared PTFE powders. He has a PhD in Chemical Engineering from the Graz University of Technology and has conducted research at academic institutions such as Purdue University, the University of Nottingham, and the Colorado School of Mines, where he developed mathematical models and numerical methods for slurry flows in fractures, gas-particle heat transfer, subsurface flows, fluidized bed heat exchangers, and membrane filtration. During his career, Dr. Municchi has conducted research on multiphase flows at all scales, from flows with resolved particles or bubbles, to large systems employing coarse-grained continuum models.

*Subject to change