Motivation

To advance sustainable manufacturing practices and promote resource efficiency, US industries need reliable measurement methods to evaluate sustainability performances such as energy and material consumption, emissions, waste, and water usage of manufacturing processes. However, the current use of ad-hoc methods and unstructured data to describe sustainability of specific manufacturing processes cannot effectively support the development of the needed reliable measurement methods. Furthermore, industry lacks the needed measurement science, and structured information base for characterizing manufacturing processes that will allow evaluation of sustainability performances and facilitate industry adoption of resulting standards for sustainable manufacturing.

There is a need to develop formal methods and standards for acquiring and exchanging information about manufacturing processes. This approach will enable manufacturers and solution providers the necessary tools and techniques to characterize manufacturing processes in a consistent and computer interpretable way. Ultimately this would lead to a collective effort by the manufacturing sector to support effective communication of computational analytics and sharing of sustainability performance data and help establish a consolidated repository for reuse of these models.

Manufacturers need models to improve operations, to protect the environment, to share information, and to compose them into systems. System characterization, whether it be the individual manufacturing process or the broader manufacturing system, defines the frame of reference needed to evaluate and improve the performance of a given system against a norm. Using valued manufacturing models, manufacturers will be better equipped to simulate, improve, and optimize key manufacturing processes.

Introduction to the competition

This competition focuses on the modeling of manufacturing processes for system-level sustainability assessment. Models can span from traditional scale down to nanoscale processes and be based on mechanical, electrical, chemical, biochemical, and bio technologies. Any process type - including batch, continuous, and discrete event - is acceptable. Since sustainability is a balance of competing objectives including cost and time as well as environmental considerations, many different types of process performance metrics may be considered. In addition, the use of the models for system-level sustainability performance is encouraged.

Objective

The purpose of the competition is create a venue to foster interest in characterizing manufacturing processes – leading to a common set of descriptive models and performance metrics that support effective and consistent system level analysis and comparisons spanning various manufacturing processes and resources. This year’s Theme is Model Reusability.

Similar to the 2018 competition, the building blocks of each submission are the Unit Manufacturing Process (UMP) models, which represent Reusable Abstractions of Manufacturing Processes (RAMP). Possible approaches that participants could take to address this year’s theme include (but are not limited to) the following:

- Demonstrating the use of a single UMP model to conduct analysis for multiple scenarios

- Linking a UMP model to traditional workflows (e.g., discrete event simulation, Life Cycle

- Assessment, Optimization, or other systems-level analysis)

- Formally describing the use bounds and feasibility constraints of the UMP model

- Identifying and quantifying sources of model uncertainties

Entry process

A submission maybe be entered in the competition by submitting a packet to the RAMP 2019 Competition Oragnizers. Entries must be received by March 4, 2019. Please refer to the *Description* section for details.

Finalists selected from the entrants (individual or group) will be expected to give an oral presentation fo their submission at the 2019 MSEC. The use of visual aids and demonstration of actual working models are highly encouraged.

Submissions should be sent to the RAMP 2019 Competition Organizer:

Dr. William Bernstein

william.bernstein@nist.gov

National Institute of Standards and Technology

Description

The submission packet should include two components: (1) one (or more) UMP model(s) as XML documents conforming to the UMP data model and (2) a 1500-3000 word report with supporting figures. All files must be packaged into a single file (ZIP) and sent to the Competition Organizer. Items that must be included in the report are:

- Project Title

- Names and permanent addresses of the participating students with one of the students indidcated as the designated contact person

- The name and signature of a faculty sponsor complete with postal address, email address, phone number, and fax number

A successful report might also include:

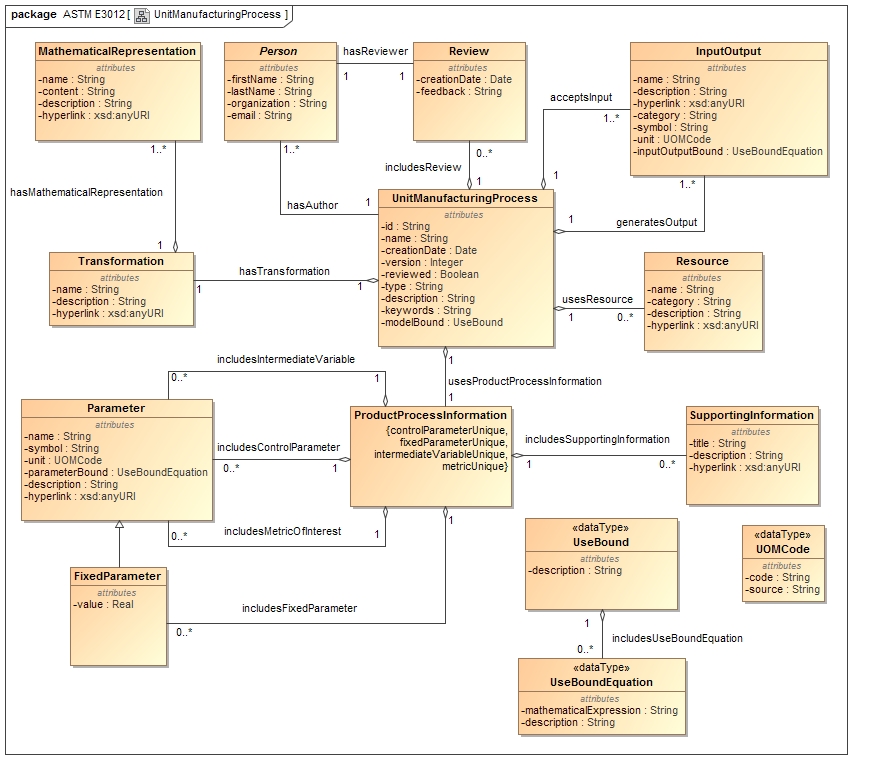

- A graphical representation, based on ASTM E3012-16, for the UMP model(s) presented

- A demonstration of how the submission adheres to the theme, Model Reusability

- Description of how the UMP model(s) have been validated

- A list of references used to populate/create the UMP model(s)

Additional guidelines for submission can be found at the end of this page.

Eligibility

Any graduate or undergraduate student who is registered in school full time through Spring of 2019 or beyond. Both individual and group projects are welcome. Individuals may participate in several entries provided each entry is on a different subject.

Finalists and Judging

Finalists will be selected on the basis of their submission packets. Judges for the competition will be from industry, academia, and/or government. The first round of judging will be a panel review of the submission packets. Finalists selected from the entrants (individual or group) will be expected to give an oral presentation of their project at the 2019 MSEC. The use of visual aids and demonstration of actual working models are highly encouraged. Finalists will be notified no later than March 22, 2019.

Judging criteria for both rounds will include yet not be limited to:

- Compliance with requriements

- Adherance to the theme

- Complexity of the model and analysis presented

- Impact of the work presented

For the final round of judging, finalists will be asked to make a 15-minute presentation with 3-5 minutes for questions at the 2019 MSEC. The final judging will be based on first round rankings with the additional scoring on the quality of the presentation (impact, timeliness, graphics, clarity).

Travel Expenses and Support

Travel expenses to the conference will be the responsibility of the students and/or faculty sponsor. However, the teams in the finalists may request travel support of up to US$500 per team from ASME MED. Further, a complimentary conference registration will be provided to the finalists (one per team). Information regarding travel support will be sent with the notification of the selected finalists for the competition. Alternatively, conference student participants may apply for competitive travel awards (covering full registration and lodging) from an anticipated NSF grant, though there are certain obligations, such as participating through the entire conference. Detailed information of NSF student travel award applications, selections and requirements will be posted on the website and sent to the student teams.

Awards

Cash prizes and awards, listed below (subject to the quality of the entries), will be presented at the live judging event at MSEC.

First Prize – $1,000

Second Prize – $600

Third Prize – $400

Additional Guidelines

Manufacturing Process Selection: You can choose any manufacturing process(es) to demonstrate the application of a UMP representation using ASTM E3012-16 and in support of the theme. ASTM is providing access to this standard free of charge for the purpose of the RAMP Challenge. To obtain a copy of the standard for use in the RAMP Challenge, click here: http://www.astm.org/nist-ramp. The standard is further described in a Journal of Manufacturing Science and Engineering paper titled “Standard representations for sustainability characterization of industrial processes.” The paper may be downloaded here: https://ws680.nist.gov/publication/get_pdf.cfm?pub_id=920168.

Properly representing your UMP model:

The identified UMP information model(s) each should include an XML instance conforming to the new UMP Schema. The UMP Schema provides the structure necessary to meet these requirements. Please refer to the UMP Schema Documentation for a detailed explanation of each element and attribute in the schema. Within the XML instance, the following must be addressed:

- Entity identification: Identify the five elements shown in the E3012-16 standard, including inputs, outputs, product and process information, resources, and transformation functions.

- Nomenclature: Describe the nomenclature of all recorded entities represented in the structured form, including any computed values in the transformation functions. This should include information such as names of the computed values, its meaning, type of the input variable, and the unit in which the data is represented in the model.

- Information sources: Source of the information used to define the UMP models, such as existing literature, industry case studies, and textbooks.

- Constraints and bounds: For each recorded parameter and the model itself, describe the feasibility bounds. For example, material density cannot be a value less than zero.

Figure 1: Conceptual Definition of a UMP

Figure 1: Conceptual Definition of a UMP

To help build the UMP model, NIST has created a web-based tool called the UMP Builder, found here: https://umpbuilder.nist.gov/. Participants are encouraged to sign up for an account and use the tool to create their UMP model(s).

Note: The Graphical Representation should match the XML instance as specified in the Information Model. The purpose of the Graphical Representation is for presentation and communication. If there are multiple UMPs submitted, a graphical representation for each UMP should be prepared.